Intrinsically Safe Radios: A Must-Have for the Chemical Industry

Explosion-Proof Radio

The chemical industry faces inherent risks due to the presence of flammable and explosive substances. Recent accidents highlight the devastating consequences of using non-intrinsically safe equipment in these hazardous environments.

In the United States, there were 270 chemical incidents in 2023, as tracked by the Coalition's online Chemical Incident Tracker, which compiles data from news reports. A tragic example occurred in early 2023 when a chemical company in Panjin, China, experienced an explosion during the pressurized sealing of an alkylation unit's inlet pipeline. This incident resulted in 13 deaths, 35 injuries, and direct economic losses of approximately 87.99 million yuan (RMB).

What is an Explosive Environments?

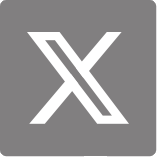

An explosive environment is defined as an area where flammable gases or combustible dusts are present in sufficient quantities to cause an explosion. Industries such as oil and gas, chemicals, coal, pharmaceuticals, and food processing frequently encounter such environments.

In environments where the leakage of explosive substances is common—like oil refineries, natural gas facilities, chemical plants, and mining operations—the combination of ubiquitous oxygen and inevitable ignition sources makes explosion protection vital.

The Need for Vigilance

To prevent explosions, it's crucial to control ignition energy and temperature. Intrinsically safe radios are designed to operate safely within these parameters, limiting energy output and using explosion-proof materials.

The Importance of Minimum Ignition Energy and Temperature Controls

The minimum ignition energy (MIE) is the smallest spark energy capable of igniting a dust cloud or a flammable gas mixture. Similarly, the ignition temperature is the lowest temperature at which a substance will ignite. Radios, which communicate via electromagnetic waves, can inadvertently produce sparks or arcs due to the conversion of electric and magnetic fields. Many radios extend their communication range by increasing RF transmission power; however, higher RF power generates more energy, potentially igniting flammable gases. Intrinsically safe radios, therefore, adhere to strict limits on RF power and energy output.

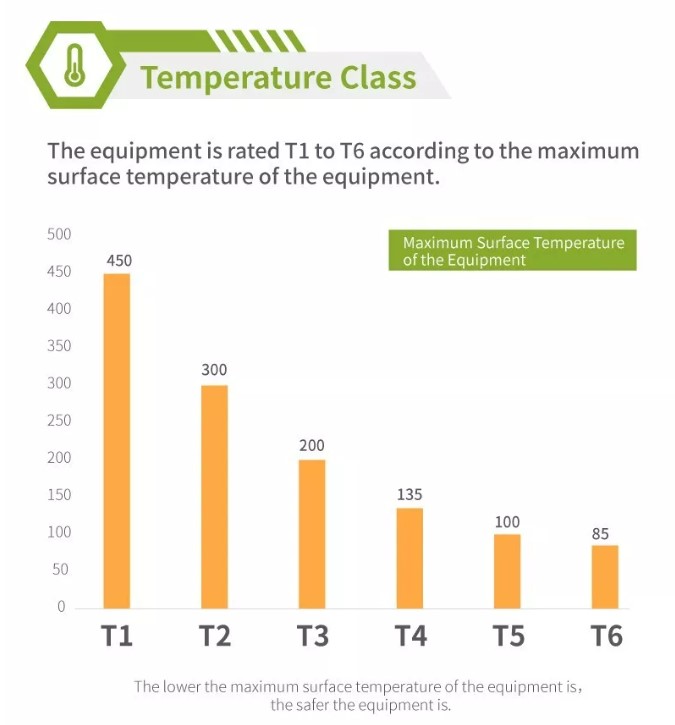

In addition to these restrictions, explosion-proof standards impose stringent controls on the surface temperatures of electrical equipment operating in explosive environments. Equipment is classified by temperature ratings (T1 to T6), where T6 represents the most stringent requirement.

Key Differences Between Intrinsically Safe and Ordinary Radios

There are two primary distinctions between intrinsically safe radios and standard radios:

1, Specialized Design: Intrinsically safe radios are engineered with specialized circuits, packaging, and structural designs that ensure RF power and energy remain below safety thresholds, meeting the communication needs of hazardous environments.

2, Explosion-Proof Materials: The body and casing of intrinsically safe radios are made from explosion-proof materials, designed to prevent static electricity, resist sparks, and endure high temperatures and pressures. This reduces the risk of triggering explosions, safeguarding users' lives.

Furthermore, it's not just the radios themselves that must be intrinsically safe—accessories like batteries, charging stations, headsets, and shoulder microphones must also comply with safety standards to ensure comprehensive protection in explosive environments.

Prioritize Safety

In industries like petrochemicals, pharmaceuticals, and storage, where the risk of explosions is ever-present, intrinsically safe radios are a non-negotiable safety measure. They provide reliable communication while minimizing production risks, safeguarding both personnel and operations.