A Day in the Life of a Petrochemical Patrol Officer: How Two-Way Radios Evolved, and So Did Safety

Explosion-Proof Radio

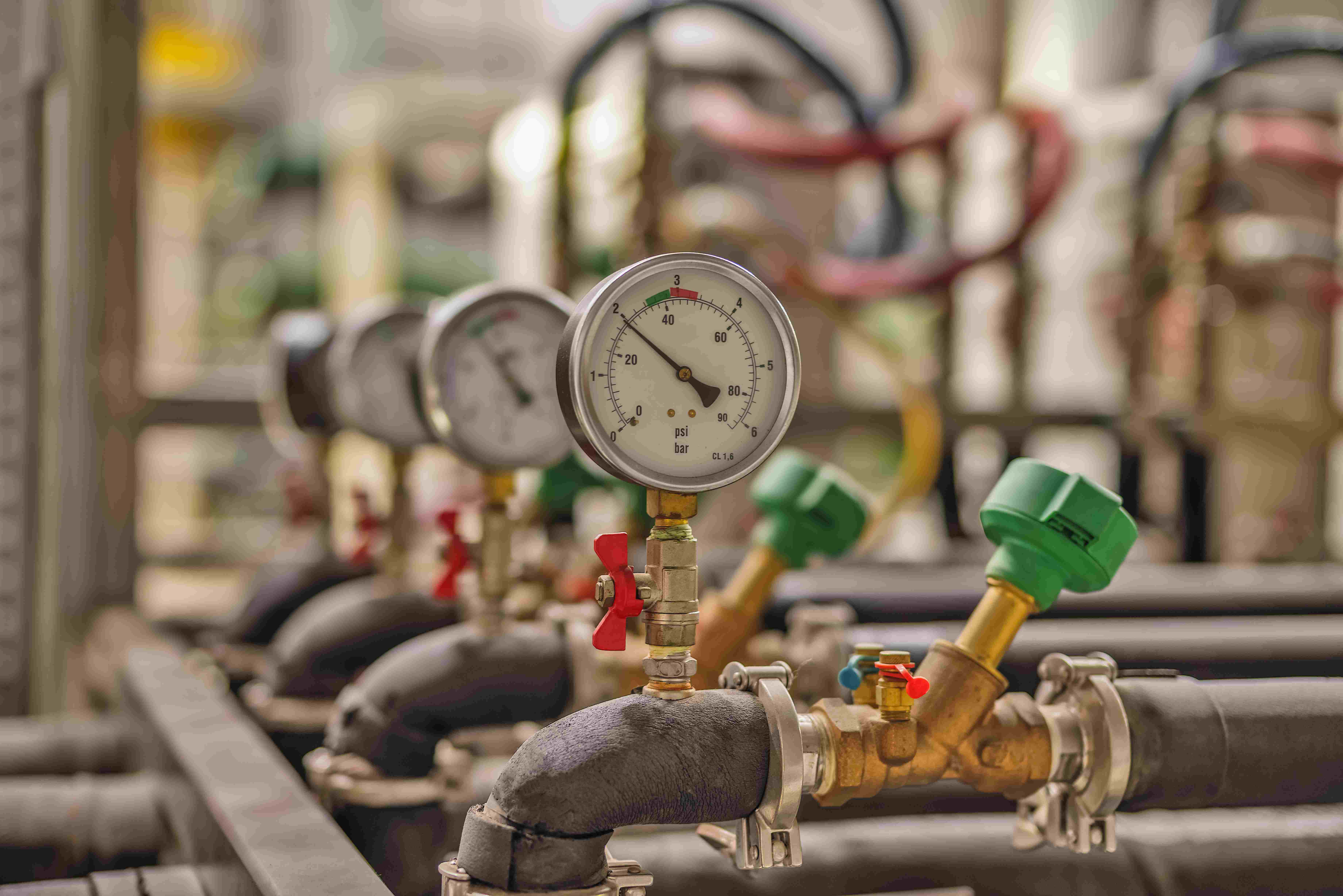

For over three decades, Mr Li has worked as a patrol officer at a large petrochemical plant on the coast of China. His job? To walk the same paths every day, checking for oil leaks, temperature spikes, gas pressure irregularities, and unusual sounds from aging machinery. It's repetitive work, but high-stakes — because in a petrochemical plant, the smallest oversight can lead to major accidents.

Over the decades, what's changed most dramatically isn't just the equipment he inspects, but the radio he carries. Because as his two-way radio evolved — from analog to digital, from narrowband to broadband — so did the plant's entire approach to safety.

This is what a day in his life looks like today.

06:00 – Smarter Shift Briefings

Mr Li starts the day with a digital patrol task pushed to his device. His Hytera smart radio shows a detailed map, the locations he'll inspect, and a list of key risks to check.

In the early years, briefings meant handwritten notes and analog radios — no data, no location, no logs. Coordination was voice-only and reactive.

Now: Radios have become smart terminals, enabling digital work order delivery, real-time updates, and multi-channel collaboration.

08:00 – Entering a High-Risk Zone

Mr Li steps through the safety gate and into what's known as a Class I hazardous area — a place where flammable gases or vapors can exist. In the old days, radios had to be left outside this zone. The analog devices weren't explosion-proof, so communication relied on shouting, hand signals, or sending someone back to relay messages. It slowed everything down — and made things far more dangerous.

Today, things look very different.

Clipped to his uniform is a modern Hytera Intrinsically Safe (IS) radio — rugged, sealed, and Explosion-proof -certified. It's designed to withstand explosive gases, thick dust, high humidity, and the kind of extreme heat you'd expect around pipelines and tanks. Even in these tough conditions, Mr Li can talk to the control room with crystal clarity.

25What's more, his new IS radio is dual-mode: it runs on both DMR (narrowband) and LTE (broadband). That means he's not just talking — he's streaming. With a single push, he sends his GPS location, status updates, and even short video clips from his wearable camera straight to the control center.

Now: He no longer has to step out of the danger zone to report an issue. Everything happens in real time. Faster response, safer work. This isn't just a better radio — it's a whole new way of keeping people safe.

10:00 – Intelligent Reporting from the Field

Mr Li spots a pressure anomaly and sends a voice message along with a photo and GPS coordinates — all through his radio. The back-end platform logs the event and alerts the relevant team. In earlier days, he would have radioed a basic report, then walked back to log the issue manually.

Now: Hytera's integrated broadband devices combine radio, camera, GPS, and mobile app tools in one rugged terminal.

13:00 – Mid-Day Team Update

During lunch, Mr Li receives a dispatch update. A nearby leak has caused route changes. All field staff receive the revised plan instantly via their radio screens. Legacy analog systems had no way to push text or map-based info. Everything depended on repeated voice calls.

Now: Digital radios enable secure, instant, and group-based communication, with voice, text, files, and video. Everything is trackable.

15:00 – Emergency Drill with Real-Time Response

The plant runs a fire drill. Mr Li triggers a distress alert with one press. The system detects his location, activates live video, and starts a pre-set emergency workflow.

His smart radio includes man-down detection, fall alarms, and LTE backup — a far cry from early radios that could only broadcast voice and required manual SOS signals.

Now: The radio is part of a larger safety ecosystem, combining AI-based alerts, GIS location tracking, and unified dispatching.

18:00 – End of Shift, Beginning of Insights

Before heading home, Mr Li reviews his patrol log — which is already synced to the backend. His voice memos, images, and checklists are automatically categorized.

The data feeds into a centralized platform for risk analysis, maintenance planning, and audit review.

Now: Radios are not just tools for talking. They're part of a digital system that turns every patrol into actionable intelligence.

The Bigger Picture: Safety Through Evolution

From analog static to encrypted digital voice. From voice-only calls to real-time video. From separate devices to an all-in-one patrol terminal. The journey of the radio mirrors the evolution of safety in the petrochemical industry: smarter, faster, and more connected.

With Hytera, this evolution continues — delivering rugged devices, broadband connectivity, AI-driven command systems, and seamless integration with plant operations. Mr Li might still walk the same paths every day — but the tools in his hands have changed everything.

And in the world of petrochemicals, that change could mean lives saved.